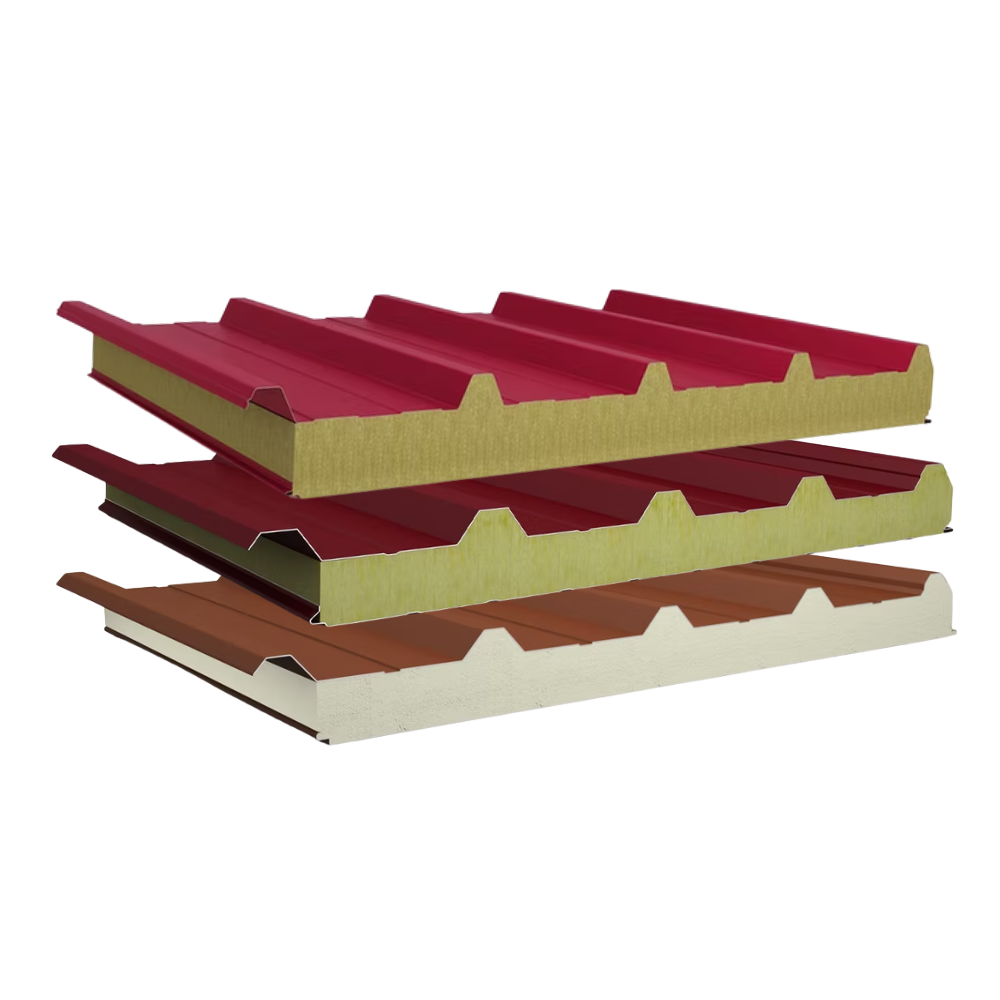

Roof and Wall thermal insulation panels consist from two roll-formed plates and polyurethane filling, and have excellent thermal insulation properties regardless of PUR of PIR filling.

The Roof external panel side is trapeze roll-formed plate with 5 ribs and reinforcements, providing high load carrying capacity of the roof panel, the minimum roof panel gradient is 5° or less, if special conditions are met.

The Wall external panel side is roll-formed plate with 4 types of structural designs, starting from flat, standard, micro and micro-sinus profile.

The internal side is commonly produced by linear roll-forming, but it can be also manufactured with micro roll-forming, or as a flat profile, according to special customer’s requirements.

Customers can also order roof panels with overhanging upper trapezoid plate, where protective strip is applied to overhanging section in production for easier cleaning of polyurethane filling. Length of the overhang is in accordance with customer’s requirement, from 70 to 300 mm.

The roof and wall panels are manufactured in thicknesses from 30 to 160 mm, with customer choosing color and thickness of plates.